Sora Rettifiche Srl

La nostra offerta comprende diverse tipologie di soluzioni da presentare ai nostri clienti: dal servizio “motore a rotazione”, che permette il ritiro immediato di un motore già ricondizionato in cambio di quello da ricondizionare, oppure la revisione del vostro motore, o in molti casi la fornitura del nuovo.

Il reparto Spedizioni collabora coi principali corrieri nazionali per spedizioni celeri in 24ore per la maggior parte degli ordini nazionali, 72/96 ore per le principali località europee.

SORA RETTIFICHE SRL è una solida realtà industriale che guarda al futuro senza dimenticare i valori aziendali che l’ hanno accompagnata per cinquant’ anni di storia e contestualmente orientandosi al progresso sotto il profilo della gestione imprenditoriale della nuova dirigenza.

SERVIZI OFFERTI

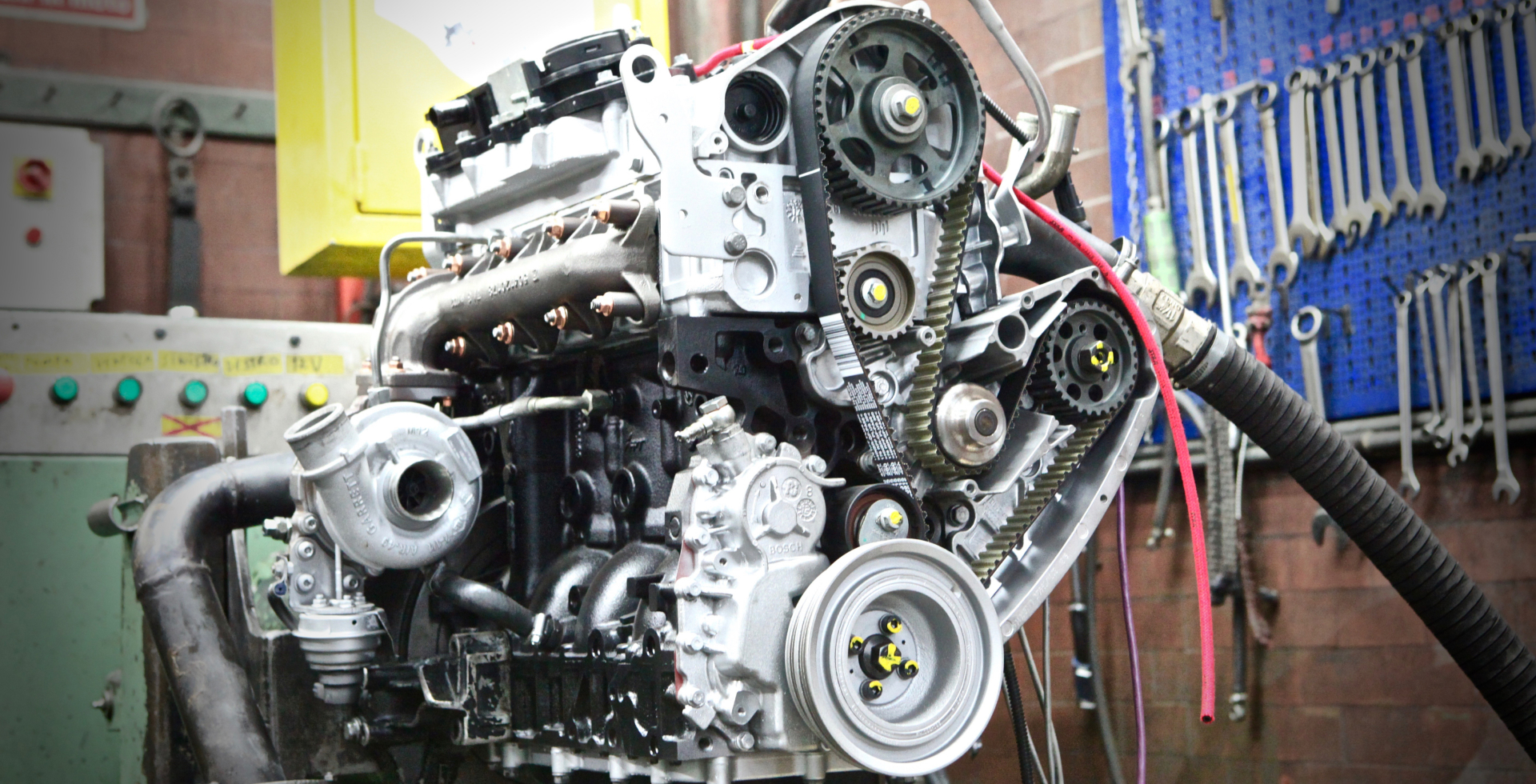

RIGENERAZIONE MOTORE

La rettifica motore viene consigliata nel momento in cui si iniziano ad avere problemi con varie componenti meccaniche del motore stesso. La revisione del motore deve essere effettuata da tecnici esperti che lavorano adeguatamente su ogni suo componente.

I Vantaggi Della Rigenerazione Del Motore!

Qualità garantita

I motori ricondizionati garantiscono affidabilità, qualità e longevità paragonabili a quelli di un pezzo nuovo e sono coperti da uguale garanzia.Risparmio

Oltre al conveniente rapporto qualità prezzo un motore ricondizionato richiede infatti un minor impiego di nuove materie prima e si stima che da 4 parti danneggiate di un motore sia possibile ottenerne 3 ricondizionate e perfettamente funzionanti.Rispetto per l’ambiente

Un motore ricondizionato consente inoltre un risparmio dell’ 80% dell’energia necessaria a produrne uno nuovo e contribuisce alla riduzione dell’inquinamento atmosferico; la sostituzione di un motore usurato con uno ricondizionato ne abbatte le emissioni inquinanti.![]()

Perchè scegliere Sora Rettifiche per rigenerare il tuo motore?

Scegliendo Sora Rettifiche il tuo motore verrà rigenerato seguendo un procedimento qualitativamente elevato, che garantisce un risultato finale eccezionale.

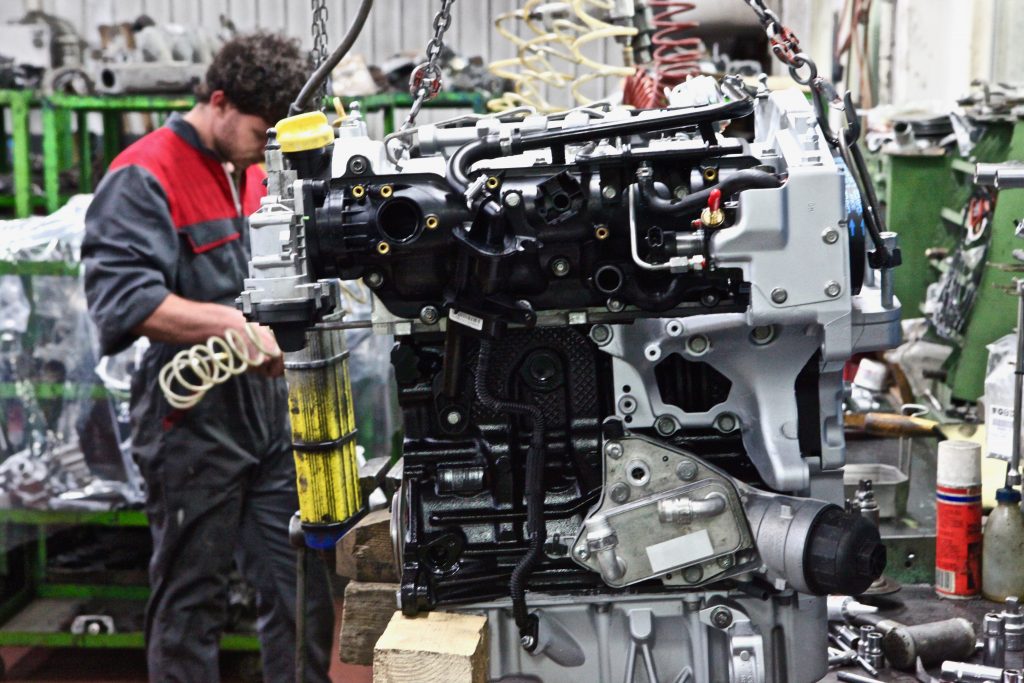

Il motore usato viene completamente smontato e i componenti da rigenerare vengono trattati nelle vasche di pulizia. Di seguito vengono lavorati nei reparti specializzati: i pezzi fondamentali del motore come basamento, albero motore, testata cilindro, albero a camme vengono rettificati, rispettando valori e tolleranze della casa costruttrice.

Tutti i componenti soggetti ad usura vengono sostituiti da componenti nuovi originali o nuovi di primo impianto. Le lavorazioni vengono eseguite nel rispetto delle indicazioni fornite dalle case costruttrici. Infine, al termine delle lavorazioni, il motore viene assemblato e collaudato.

![]()

Scopri il nostro servizio di rigenerazione motori

Motori veicoli commerciali

La revisione o fornitura di motori revisionati per veicoli commerciali è uno dei servizi in cui SORA RETTIFICHE è specializzata.

La revisione di motori per veicoli commerciali, mezzi che oltre ad avere funzione di trasporto merci sono fondamentali per l’attività lavorativa, è preferibile rispetto all’ acquisto di un mezzo nuovo perché si tratta di un procedimento veloce e più economico.

La revisione, infatti, permette un risparmio in termini di costi e di tempo; tutti i motori vengono sottoposti al collaudo in sale prova, per testarne il buon funzionamento. A collaudo positivo ultimato, il motore viene preparato per la consegna al cliente.

I motori di maggiore movimentazione che revisioniamo sono i Fiat e Iveco.

La Gamma Fiat Ducato/Iveco Daily 2.3mjt marcata F1AE, 3.0mjt marcata F1CE, ad esempio, possono essere forniti negli allestimenti semicompleto o completo.Se ci si trova nella situazione di dover cambiare un motore non più utilizzabile, per usura o per altri motivi, il servizio di fornitura di motori per veicoli commerciali permette di acquisire un motore con le stesse prestazioni di uno nuovo ed avere in aggiunta un notevole risparmio in termini economici.

Oltretutto, acquistare un motore ricondizionato aiuta anche l’ambiente, permettendo un risparmio di circa l’80% dell’energia necessaria alla produzione di un motore nuovo e un notevole abbattimento delle emissioni rispetto ad uno ormai usurato.

AFFIDABILITÀ e LONGEVITÀ del prodotto revisionato

La professionalità dei nostri tecnici garantisce un servizio di alta qualità, in grado di offrirvi motori con le stesse funzionalità dei nuovi.PROFESSIONALITÀ del personale altamente qualificato

La competenza dei componenti del nostro team garantisce un alto livello di professionalità. L’azienda, inoltre, è certificata ISO 9001:2015, a sottolineare maggiormente la qualità dei processi aziendali, delle realizzazioni di prodotti e dell’erogazione dei servizi con particolare attenzione alla soddisfazione dei clienti.ESPERIENZA da oltre 50 anni nella revisione dei motori

La storia di SORA inizia negli anni ’60, evolvendosi continuamente nel corso del tempo fino al giorno d’oggi, quando la solida realtà industriale si è orientata al progresso grazie ad una nuova gestione imprenditoriale.Motori truck

Il funzionamento del motore si distingue per la vasta gamma di componenti interni che lo compongono ed un elevato livello di complessità. Per questo motivo le operazioni di ricondizionamento o riparazione sono processi estremamente impegnativi che è meglio lasciare agli specialisti del settore.

È inoltre possibile mantenere degli standard elevati anche se si possiede un veicolo “vecchio”. Se il vostro motore ha molti chilometri, quando si tratta di manutenzione o riparazione, per contenere i costi, non è necessario rinunciare alla qualità dei ricambi.

La revisione o riparazione del motore viene effettuata con macchinari specifici che ne garantiscono la qualità e l’affidabilità pari a quella che si avrebbe con un motore nuovo ma ad un prezzo inferiore.

I motori di maggiore movimentazione che revisioniamo sono i Mercedes, Man e Iveco.

- Tecnici specializzati con anni di esperienza, fondamentali per una revisione a regola d’ arte

- Affidabilità dei ricambi utilizzati, affidandoci ai migliori costruttori e concessionari

- La rigenerazione riduce l’impatto ambientale, in quanto recupera parti esistenti anziché utilizzare componenti nuovi.

- L’azienda fornisce un anno di garanzia su tutti i suoi prodotti revisionati.

Motori per camper

- Tecnici specializzati con anni di esperienza, fondamentali per una revisione a regola d’ arte

- Affidabilità dei ricambi utilizzati, affidandoci ai migliori costruttori e concessionari

- La rigenerazione riduce l’impatto ambientale, in quanto recupera parti esistenti anziché utilizzare componenti nuovi.

- Garanzia 12 mesi su tutti i suoi prodotti revisionati.

La revisione e la rigenerazione del motore per camper è molto importante perché permette di mettere in sicurezza il mezzo, migliorandone le prestazioni. E’ molto importante affidare la revisione del motore a professionisti del settore.

Se ci si trova nella situazione di dover cambiare un motore non più utilizzabile, per usura del tempo o per altri motivi, il servizio di fornitura di motori revisionati fiat Ducato per camper permette di acquisire un motore con le stesse prestazioni di uno nuovo ed avere in aggiunta un notevole risparmio di prezzo sul costo.

Oltretutto, acquistare un motore ricondizionato aiuta anche l’ambiente, permettendo un risparmio di circa l’80% dell’energia necessaria alla produzione di un motore nuovo e un notevole abbattimento delle emissioni rispetto ad uno ormai usurato.

AFFIDABILITÀ e LONGEVITÀ del prodotto revisionato

La professionalità dei nostri meccanici garantisce un servizio di alta qualità, in grado di offrirvi motori con le stesse funzionalità dei nuovi.PROFESSIONALITÀ del personale altamente qualificato

La competenza dei componenti del nostro team garantisce un alto livello di professionalità. L’azienda, inoltre, è certificata ISO 9001:2015, a sottolineare maggiormente la qualità dei processi aziendali, delle realizzazioni di prodotti e dell’erogazione dei servizi con particolare attenzione alla soddisfazione dei clienti.ESPERIENZA da oltre 50 anni nella revisione dei motori

La storia di Sora inizia negli anni ’60, evolvendosi continuamente nel corso del tempo fino al giorno d’oggi, quando la solida realtà industriale si è orientata al progresso grazie ad una nuova gestione imprenditoriale.Motori settore agricolo

Sora Rettifiche può intervenire nella rigenerazione del tuo motore, portandolo a tutti gli effetti ad un motore a zero ore.

Presso di noi il tuo motore verrà smontato completamente, revisionato rispettando gli standard della Casa Madre, utilizzando ricambi nuovi originali o di primo impianto, in sostituzione dei quelli usurati . Il motore verrà provato al banco prova e pronto per essere installato.

- Risparmio economico rispetto all’ acquisto di un motore o di un mezzo nuovo

- Preventivo rapido ad hoc per il problema riscontrato sul tuo motore

- Utilizzo di ricambi ORIGINALI o AFTERMARKET di qualità equivalente

- Ritiro e consegna motore

- Professionisti del settore a tua disposizione pre e post vendita

- Garanzia 12 mesi

Motori auto d'epoca

Il motore a scoppio è composto da diversi componenti, in particolare quelli che formano il cuore del motore sono soggetti ad usura.

I nostri operatori altamente specializzati sono in grado di riportare a nuovo i vari componenti. Ad esempio il basamento, la testa cilindri, le valvole e altre componenti, vengono sottoposte ad una serie di lavorazioni di rettifica e controlli.

Il risultato raggiunto tramite le operazioni di rettifica è quello di ottenere un motore praticamente nuovo.

- Tecnici specializzati con anni di esperienza, fondamentali per un restauro a regola d’arte

- Affidabilità dei ricambi utilizzati, affidandoci ai migliori ricambisti per auto storiche

- Garanzia 12 mesi

RETTIFICA E REVISIONE COMPONENTI

Sora Rettifiche è in grado di eseguire qualunque intervento specifico su motori e componenti.

Collaudi motori sui 4 banchi prova, anche a gestione elettronica, con rilascio certificato (potenza max 800cv / 900 cv di picco)

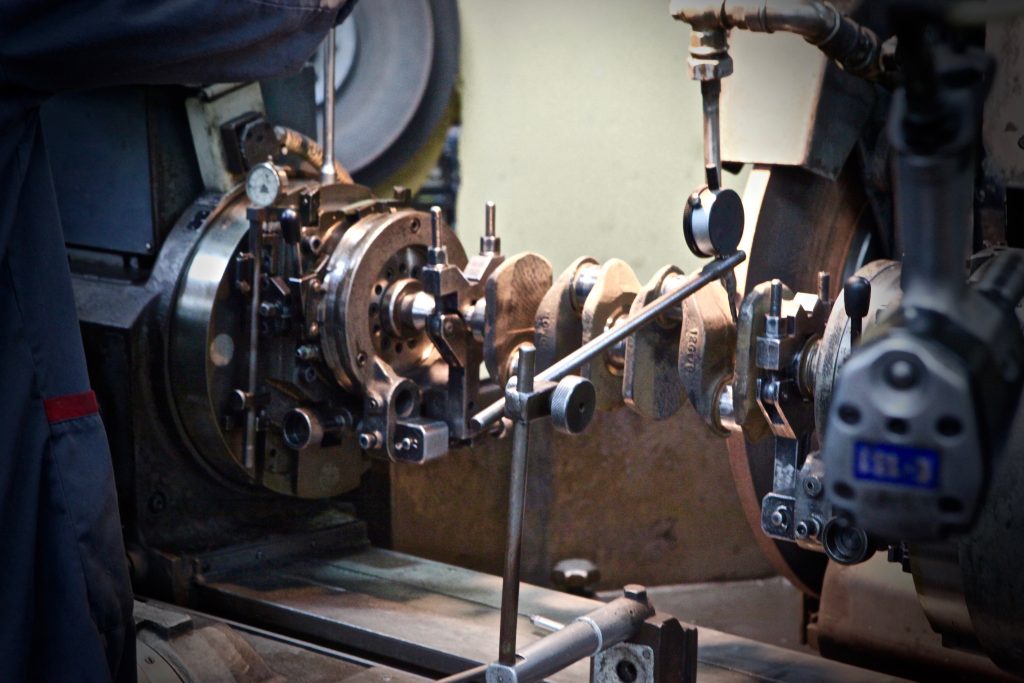

Equilibrature elettroniche con macchina fissa (a 4 supporti; portata da 100 g a 450 kg) o con macchina portatile, entrambe ad alta precisione

Rettifica alberi motore (lunghezza max. 3.000 mm)

Rettifiche industriali Revisione cambi e differenziali

Revisione monoblocchi

Revisione pompe iniezione

Revisione turbocompressori

Ricostruzione alberi a cammes

Ricostruzione testate

Riparazione basamenti in ghisa

Riporti in saldatura su ghisa, alluminio e acciaio ( i nostri addetti specializzati sono in grado di ricostruire integralmente pezzi fuori commercio rendendo possibile il restauro di motori d’ epoca – Possiamo eseguire la barenatura degli alloggi bronzine banco sui basamenti )

Ogni altra lavorazione meccanica

ALCUNE LAVORAZIONI COMPONENTI

Sei reparti interni per un servizio unico

La produzione di Sora Rettifiche si articola in sei reparti: Rettifica, Testate, Assemblaggio Motori, Saldatura-Ricostruzione mediante riporti di ripristino, Collaudo, Produzione in serie; con operatori specializzati e macchine ad alta tecnologia per le lavorazioni di precisione.

![]()

Servizi Motore: dalla rotazione alla rigenerazione

Sora Rettifiche offre tutte le possibili soluzioni, dal servizio motore a rotazione che permette la consegna immediata di un motore già ricondizionato in cambio di quello da revisionare, con un’evidente riduzione dei tempi di fermo del veicolo, al ricondizionamento diretto del motore del cliente fino alla fornitura del motore nuovo.

![]()

Tecnologia

Sora Rettifiche si avvale delle più moderne tecnologie disponibili nel campo della rettifica/revisione, in grado di garantire il più alto livello qualitativo con margini di errore infinitesimali.

– Macchina a controllo numerico specifica per rettifica sedi valvole Newen

– Macchina equilibratrice elettronica statica e mobile

– 4 banchi prova anche a gestione elettronica con rilascio del certificato![]()

MOTORI REVISIONATI O NUOVI

Operiamo nella produzione e commercializzazione di motori e componenti sia revisionati che nuovi di tutte le marche per: autovetture, macchine agricole, autocarri, autobus, macchine movimento terra, industriali, cogenerazione, ferroviario, marino.

Offriamo il servizio motore a rotazione che permette la consegna immediata di un motore già ricondizionato in cambio di quello da usato, con un’evidente riduzione dei tempi di fermo del veicolo.

Che cosa si intende per motore revisionato?

Si tratta di un motore usato che viene sottoposto ad un processo di “rigenerazione” mediante lo smontaggio di tutte le sue parti. Rigenerare un motore significa portarlo a nuova vita.VANTAGGI

![]() Prezzi Competitivi

Prezzi Competitivi![]() Qualità pari all’originale

Qualità pari all’originale![]() Riduzione tempi approvvigionamento

Riduzione tempi approvvigionamento![]() garanzia 12 mesi

garanzia 12 mesiALLESTIMENTI MOTORI REVISIONATI

Magazzino Motori

Assortimento di motori revisionati da noi in Stock, subito disponibili

Pronta consegna in Italia e all’ estero

![]()

VUOI RIGENERARE IL TUO MOTORE?

Siamo a tua disposizione, compila il modulo per richiedere maggiori informazioni e ti forniremo tutte le indicazioni necessarie per il procedimento!

Lasciaci la tua email per rimanere in contatto.

Riceverai novità e aggiornamenti !

CONTATTACI

I nostri commerciali sono a tua disposizione per dare una rapida risposta alle tue richieste.

Hai bisogno di informazioni o chiarimenti?

Contattaci al numero di telefono 0546.628911 dal lunedì al venerdì dalle 8.00 alle 12.30 dalle 14.00 alle 18.30, oppure compila il form qui sotto con i tuoi dati, formulando la tua richiesta.

Ti risponderanno i nostri tecnici il prima possibile!

CONTATTI

COMMERCIALE

Fiorio Alessandro

Tel. 0546 628 951

Email: alessandro@sorarettifiche.it

Tabanelli Matteo

Tel. 0546 628 953

Email: matteo@sorarettifiche.it

DOVE SIAMO

VIENI A TROVARCI

Via Boaria, 52

48018 – Faenza (RA) – ITALY

Orari

Lunedì/Venerdì 8:00-12:30 / 14:00-18.30

Sabato CHIUSO